Will Fresh Gas/oil Mix Get Weedeater Running Again

Gas Weed Eater Won't Starting time? Try This

Weed eater, weed whacker, string trimmer – no matter what you call it, hither's how to become it running again.

No matter what you telephone call it – weed eater, weed whacker, string trimmer – chances are at some point it won't commencement. Few things are more annoying than destroying your shoulder trying to start a gas weed eater when in that location'southward piece of work to do.

Fortunately, gas weed-eater engines are pretty elementary, and then most DIYers with a few tools and some basic know-how can troubleshoot a stubborn trimmer and become it running.

Guidelines For Troubleshooting A Gas Weed Eater That Won't Showtime

1) Bank check The Gasoline

Gasoline can interruption downward in equally little as 30 days, specially today's ethanol-containing gas.

Homeowners sometimes stash their string trimmer in the garage at flavour's end without stabilizing the gas. Oxygen has all winter to break down and ruin the gasoline, leaving yous with a trimmer that won't get-go in the spring.

If your trimmer falls into this category, empty the old gas from the fuel tank and supplant it with fresh fuel.

If your weed eater won't starting time, trying removing the air filter and spraying carburetor cleaner into the intake.

2) Clean The Carburetor

Once gas breaks downwards, varnish, gums and other droppings can form inside the carburetor and clog the tiny fuel passages. This prevents fuel from reaching the combustion bedroom and igniting, leaving y'all to struggle with a trimmer that won't start.

Remove the air filter and spray carburetor cleaner into the intake. Allow it sit for several minutes to help loosen and dissolve varnish. Replace the filter and try starting the trimmer.

If this doesn't solve the problem, consider disassembling the carburetor to give information technology a more than thorough cleaning.

Beware, however – taking apart a carburetor marks a point-of-no-return, of sorts. Agreement how the delicate gaskets, tiny screws and needle valves go back together tin be a challenge, even on a relatively simple cord-trimmer carburetor. Take pictures with your telephone throughout the procedure to help reassembly. Clean all the openings and passages with carburetor cleaner.

If you're reluctant to take apart the carb, visit the servicing dealer.

Remove the spark plug and use calorie-free sandpaper to make clean electrode deposits to assistance prepare a gas trimmer that won't beginning.

3) Clean/Replace Spark Plug

Oil deposits and carbon can foul the spark plug in a ii-stroke engine if a low-quality oil is used. Deposits on the electrode preclude the plug from firing properly, which tin can reduce performance or prevent the engine from running altogether.

Plugs are inexpensive, so replace information technology if information technology's fouled. If you don't have a new plug available, clean the deposits from the electrode with light-duty sandpaper and bank check the gap. Consult the owner'due south transmission for the right gap size.

If you know the spark plug is expert, but the engine still doesn't produce spark, the gyre is likely to blame and requires replacement.

Direct compressed air from the inside of the air filter toward the outside to remove debris that may be restricting airflow.

4) Clean/Replace Air Filter

A clogged air filter prevents the engine from receiving sufficient air to operate properly.

Before removing the air filter, brush away loose debris from effectually the filter comprehend and filter element. Tap rigid filters on a tabletop or the palm of your manus to dislodge any dirt or debris. Compressed air also works well. Make sure y'all direct air through the filter from the inside to avoid lodging droppings deeper in the filter.

Avoid washing paper filters as this can plummet their micro-fine construction. Cream filters, however, tin can easily be washed using mild detergent and warm h2o.

As with the spark plug, however, replacement is often the best practice, especially if the filter is excessively dirty.

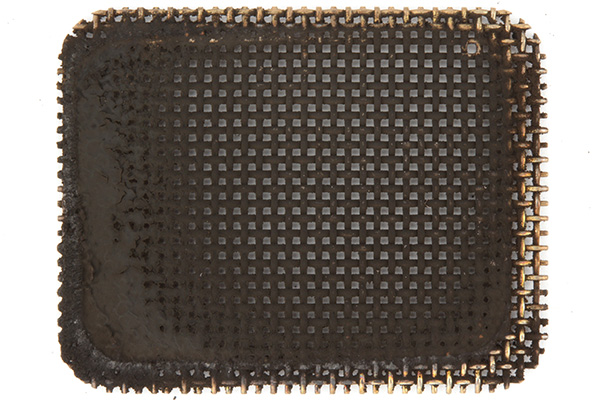

A spark-arrestor screen chock-full with deposits can asphyxiate off airflow plenty to foreclose the trimmer from starting.

5) Make clean The Spark-Arrestor Screen

On many trimmers, a small-scale screen covers the exhaust outlet and prevents sparks from exiting the muffler and potentially starting a fire.

As with plug fouling, too much oil in the gasoline, inferior oil and continued low-rpm operation tin plug the screen with carbon deposits. This prevents exhaust-gas flow, which leads to power loss. In extreme cases, heavy deposits choke airflow enough to go out you with a weed eater that won't offset.

To set the problem, remove the spark-arrestor screen and spray it with a heavy-duty cleaner, like AMSOIL Power Foam®, to soften the deposits before cleaning the screen with an abrasive pad. Reinstall the screen and exam the trimmer.

Replace the screen altogether if it's excessively plugged with carbon.

SYNTHETIC VS. CONVENTIONAL

Although y'all might know that synthetic oils outperform conventional oils, you lot might not understand why. The differences begin at the molecular level.

Larn More

6) Switch To A Better Two-Stroke Oil

Low-quality oil that leads to heavy carbon is often to arraign for most of the bug on this list.

Using a expert two-stroke oil that burns cleanly and helps prevent carbon deposits is one of the easiest maintenance practices you can perform to ensure your gas trimmer starts easily, runs well and concluding for years.

AMSOIL SABER® Professional Synthetic ii-Stroke Oil withstands high heat to fight carbon in gas string trimmers and other two-stroke equipment. It'southward tested and proven at any mix ratio upward to 100:1, offering the convenience of one mix ratio for all your equipment. Plus, it'due south formulated with gasoline stabilizer to help proceed fuel fresh during brusk-term storage.

The images here testify AMSOIL SABER Professional's superior cleanliness backdrop. It's just ane reason professional landscapers, similar Duluth Lawn Care, only trust AMSOIL products.

AMSOIL SABER Professional mixed at 100:1 delivers better protection confronting ability-robbing deposits than other oils mixed at fifty:ane.

Follow the gas trimmer troubleshooting guidelines on this list to get your string trimmer dorsum upward and running…and to give your shoulder a break.

More like this

Source: https://blog.amsoil.com/weed-eater-wont-start-try-this/

0 Response to "Will Fresh Gas/oil Mix Get Weedeater Running Again"

Post a Comment